Introduction to Industrial Rubber Compounds

Industrial applications require materials that can withstand extreme conditions, including high temperatures, chemical exposure, mechanical stress, and abrasion. Rubber compounds are essential in manufacturing processes, providing critical solutions in seals, gaskets, hoses, vibration dampers, and other industrial components. The demand for high-performance rubber compounds continues to rise as industries seek materials that offer reliability, safety, and long-term durability.

This article delves into the importance of rubber compounding in industrial applications, the challenges faced in developing high-performance materials, and the innovations that are pushing the boundaries of industrial rubber.

Why High-Performance Rubber is Essential for Industrial Use

Industrial environments are often harsh, with equipment exposed to extreme wear, tear, and environmental conditions. In these environments, rubber parts must not only provide reliable sealing, vibration isolation, and noise reduction but also resist chemicals, oils, and abrasives that could degrade standard rubber materials.

High-performance rubber compounds provide enhanced properties such as improved resistance to high temperatures, chemical stability, tear resistance, and flexibility. These attributes are crucial for maintaining operational efficiency and ensuring the longevity of industrial machinery and equipment.

Innovations in Rubber Compounds for Industry

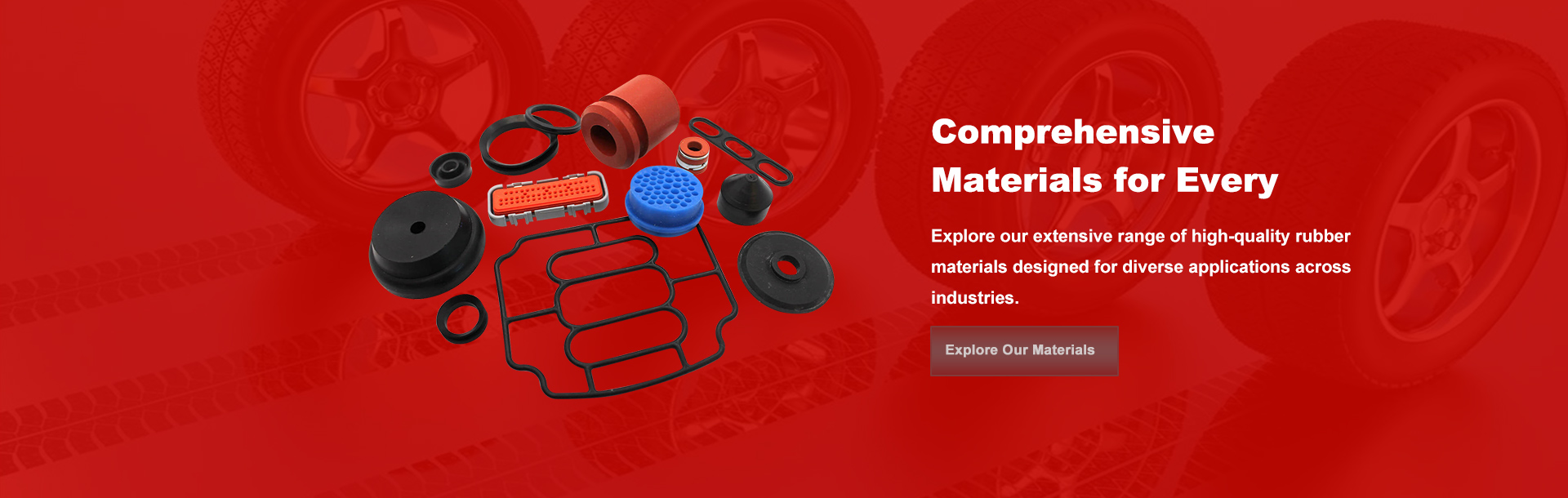

Recent advancements in rubber compounding technology have led to the development of specialized rubber materials tailored for specific industrial applications. For example, fluoroelastomers and silicone rubber compounds are increasingly used in industries like chemicals, oil and gas, and food processing. These materials offer excellent resistance to aggressive chemicals and high temperatures, making them ideal for seals, gaskets, and other components in critical systems.

Additionally, the integration of nanomaterials and advanced fillers in rubber compounds is enhancing the mechanical properties of industrial rubber products. These innovations improve the strength, wear resistance, and durability of rubber components, even under extreme mechanical loads.

Addressing Sustainability in Industrial Rubber

As industries worldwide face increasing pressure to adopt sustainable practices, the rubber industry is responding by developing eco-friendly rubber compounds. These compounds are made from renewable resources, such as natural rubber, and designed to be more easily recyclable, reducing the environmental impact of rubber waste.

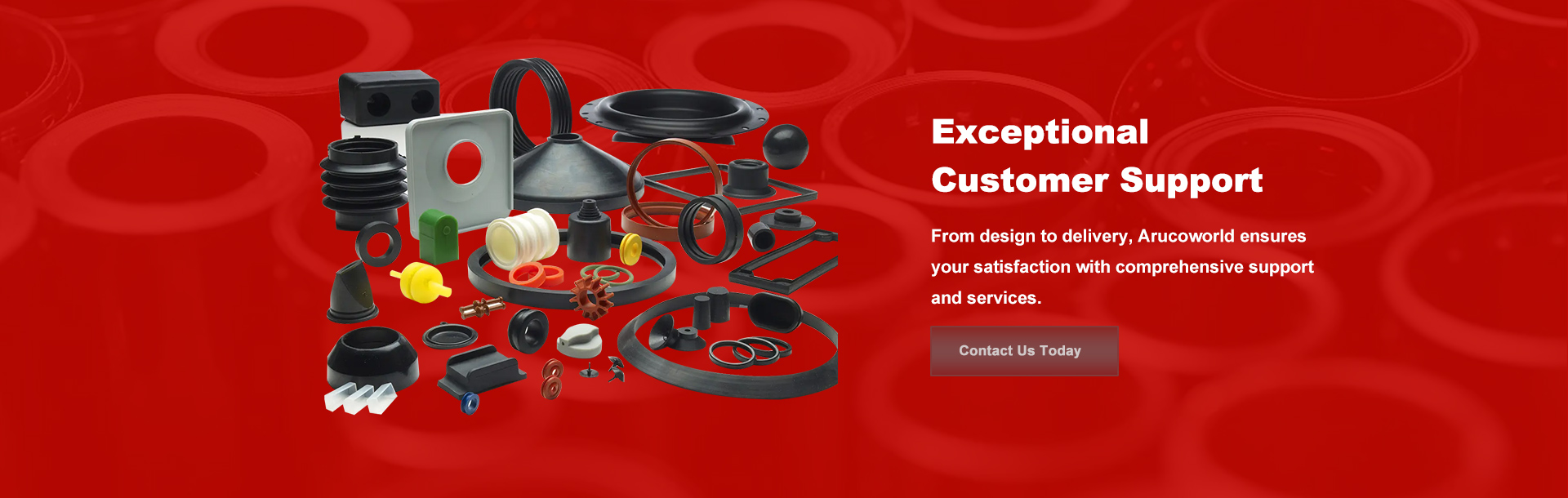

At Arucoworld, we prioritize sustainability in our industrial rubber products, incorporating green materials and processes that minimize environmental impact without compromising on performance. Our commitment to sustainability is helping our clients meet both operational and environmental goals.

The Future of Industrial Rubber Compounds

The future of industrial rubber compounding lies in developing materials that offer even greater resistance to extreme conditions, such as higher temperatures, aggressive chemicals, and more intensive mechanical stress. In addition, the continued integration of automation and precision manufacturing will improve the consistency and quality of rubber components.

Moreover, as industries move toward more sustainable practices, the demand for recyclable, bio-based, and high-performance rubber materials will continue to grow.

Conclusion

High-performance rubber compounds are essential for ensuring the reliability and efficiency of industrial operations. With innovations in material science, including the development of specialized compounds for specific applications and a growing focus on sustainability, the future of industrial rubber compounding is set to deliver even greater performance and environmental benefits.

Arucoworld is dedicated to providing industrial rubber solutions that not only meet the evolving needs of industries but also contribute to a more sustainable future.