Introduction to Rubber in Industrial Applications

Rubber compounds have become indispensable in various industrial applications due to their versatility, resilience, and durability. Whether used in machinery components, seals, gaskets, or protective coatings, rubber materials provide vital functions that improve the performance, efficiency, and longevity of industrial systems. The evolution of rubber technology has led to the development of advanced rubber compounds that meet the ever-growing demands of modern industries.

Why Rubber Compounds Are Crucial in Industrial Applications

Industrial applications require materials that can endure harsh conditions such as high temperatures, mechanical stress, and exposure to chemicals, oils, and solvents. Rubber compounds, particularly those made from synthetic rubbers such as nitrile, EPDM, and fluoroelastomers, offer superior resistance to these elements, making them ideal for sealing, vibration damping, and protective functions.

Rubber materials also provide flexibility and elasticity, which are essential for minimizing wear and tear in industrial machinery and equipment. For example, rubber gaskets and seals are used in pumps, compressors, and valves to prevent leakage and ensure efficient operation, while rubber dampers are used to absorb vibrations and reduce noise in industrial equipment.

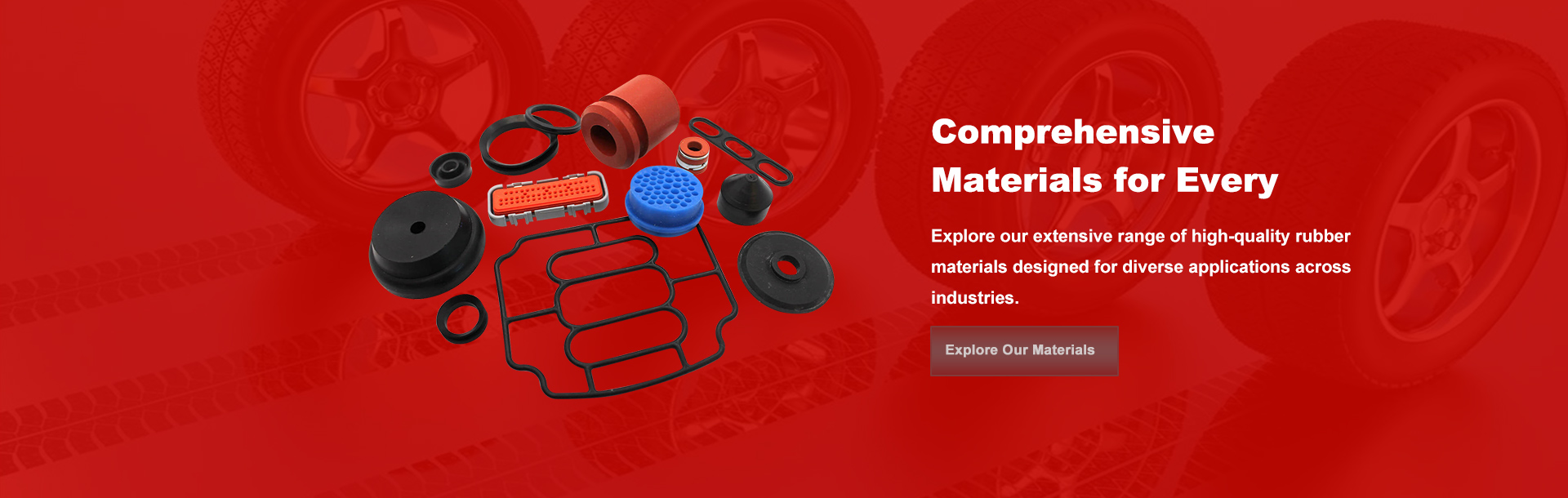

Arucoworld’s Industrial Rubber Solutions

At Arucoworld, we specialize in providing high-performance rubber compounds designed for the toughest industrial environments. Our rubber materials are engineered to withstand the mechanical stresses and environmental conditions commonly encountered in industries such as manufacturing, oil and gas, automotive, and heavy machinery. We offer custom rubber solutions that help extend the lifespan of industrial equipment, improve safety, and enhance operational efficiency.

Our rubber compounds are formulated to meet the specific needs of each application, offering properties such as heat resistance, chemical resistance, and abrasion resistance. Whether it’s a seal for a chemical pump or a vibration isolator for heavy machinery, Arucoworld provides rubber products that deliver reliable performance in demanding industrial settings.

Key Challenges in Industrial Rubber Applications

One of the biggest challenges in using rubber compounds for industrial applications is ensuring that the materials retain their performance over time, especially under extreme conditions. High temperatures, exposure to chemicals, and mechanical stresses can degrade rubber compounds, leading to failure or reduced efficiency.

Additionally, industrial rubber products must meet strict regulatory standards, including those related to safety, environmental impact, and durability. Achieving this balance while ensuring cost-effective manufacturing is a critical challenge for the industry.

Future Trends in Industrial Rubber Compounds

The future of industrial rubber applications will see the continued development of high-performance materials that offer better resistance to heat, chemicals, and aging. Advances in material science are expected to yield rubber compounds that can withstand more extreme environments and offer longer service life.

In addition, the growing demand for sustainable and eco-friendly solutions in industry is likely to influence the development of recyclable or bio-based rubber compounds. Automation and additive manufacturing technologies may also improve the precision and customization of rubber components for industrial applications, allowing for greater design flexibility and performance.

Conclusion

Rubber compounds are critical to ensuring the reliability, performance, and longevity of industrial systems. From sealing and vibration dampening to chemical resistance and durability, rubber materials provide essential functions across a wide range of industries. Arucoworld’s expertise in providing tailored rubber solutions ensures that industrial operations remain efficient, safe, and cost-effective, even in the most demanding environments.