Introduction to Rubber in HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems are essential to maintaining a comfortable and safe environment in buildings and industrial spaces. The performance and efficiency of HVAC systems depend on the integration of durable, high-performance materials, including rubber. Rubber components such as seals, gaskets, and vibration isolators play a critical role in ensuring the proper functioning and longevity of HVAC systems.

Why Rubber is Vital for HVAC Efficiency

Rubber materials are used in HVAC systems for their flexibility, sealing properties, and resistance to heat and chemicals. Seals and gaskets made from rubber ensure airtight connections in ducts and vents, preventing leaks that can lead to energy inefficiency. Additionally, vibration isolators made from rubber reduce noise and vibration generated by compressors, fans, and pumps, ensuring quieter and more efficient operation.

Rubber materials also contribute to energy savings by reducing heat loss and preventing the intrusion of external contaminants into the system. Their resistance to moisture and chemical degradation ensures that HVAC systems remain functional and safe over time, even in challenging environments.

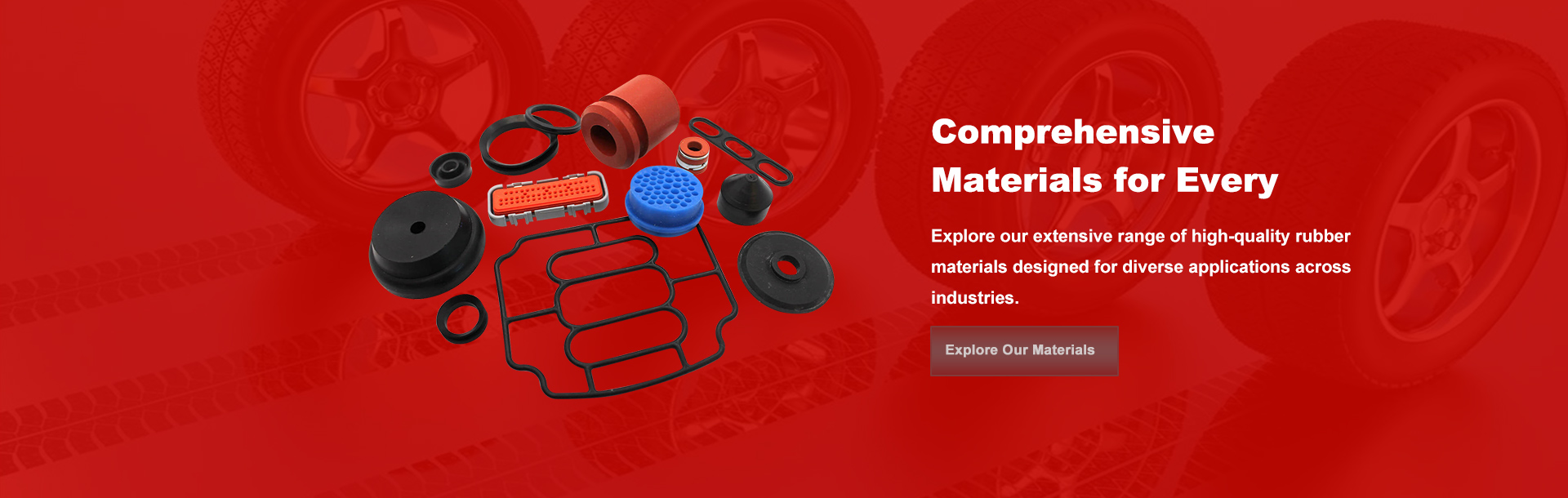

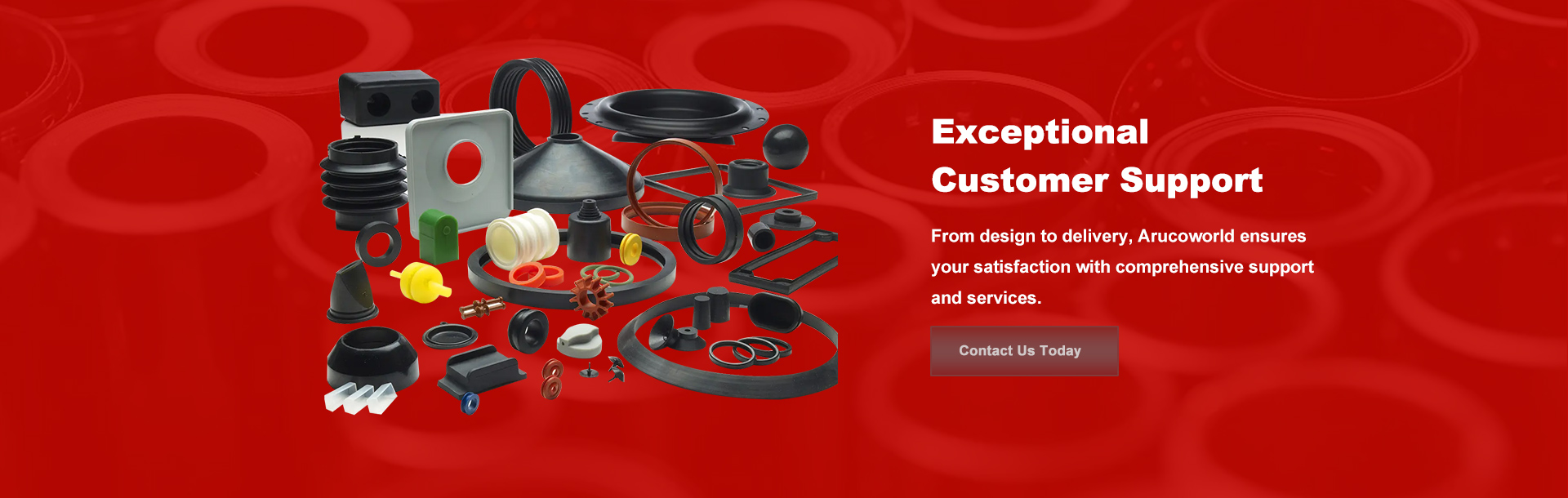

Arucoworld’s Rubber Solutions for HVAC Systems

Arucoworld provides high-performance rubber solutions designed to improve the efficiency and performance of HVAC systems. Our seals, gaskets, and vibration isolators are engineered to meet the demanding requirements of HVAC applications, ensuring long-lasting performance and energy efficiency. We work closely with HVAC manufacturers to provide custom rubber products that are tailored to the specific needs of their systems.

Key Challenges in Rubber for HVAC Systems

One of the primary challenges in using rubber for HVAC systems is ensuring that the rubber materials can withstand extreme temperatures and environmental conditions without degrading. Over time, exposure to UV light, ozone, and fluctuating temperatures can cause rubber to degrade, which can lead to leaks, reduced efficiency, and system failure.

Ensuring that rubber components remain flexible and maintain their sealing properties in such challenging conditions is crucial to ensuring the optimal performance of HVAC systems. Additionally, rubber materials must be resistant to the chemical substances commonly found in HVAC systems, such as refrigerants, oils, and acids.

Future Trends in Rubber for HVAC Systems

The future of HVAC systems is moving toward more energy-efficient and environmentally friendly solutions. Rubber materials will continue to play an essential role in ensuring the long-term performance of these systems, especially as manufacturers seek to develop products that reduce energy consumption and improve indoor air quality.

The development of advanced rubber compounds that offer enhanced resistance to heat, moisture, and chemical exposure will be key to improving the reliability and efficiency of HVAC systems. Additionally, the use of recycled rubber materials in HVAC applications may become a growing trend as the industry seeks to reduce its environmental impact.

Conclusion

Rubber materials are critical for the efficiency and performance of HVAC systems, offering vital functions such as sealing, vibration isolation, and resistance to extreme temperatures. Arucoworld’s custom rubber solutions ensure that HVAC systems operate efficiently, reducing energy costs and enhancing overall performance. As the demand for energy-efficient and environmentally sustainable HVAC solutions grows, rubber will continue to play a key role in meeting these challenges.