Introduction to Aerospace Rubber Materials

Rubber is widely used in the aerospace industry for components that must perform under extreme conditions, including high altitudes, temperature fluctuations, and high mechanical stress. Aerospace rubber materials must be highly durable, flexible, and resistant to environmental factors like ozone and UV radiation.

Why Aerospace Needs Specialized Rubber

In aerospace, rubber components are critical in ensuring the safety and performance of aircraft systems. Seals, gaskets, vibration isolators, and hoses made of high-quality rubber materials ensure that critical components function effectively and reliably during flight.

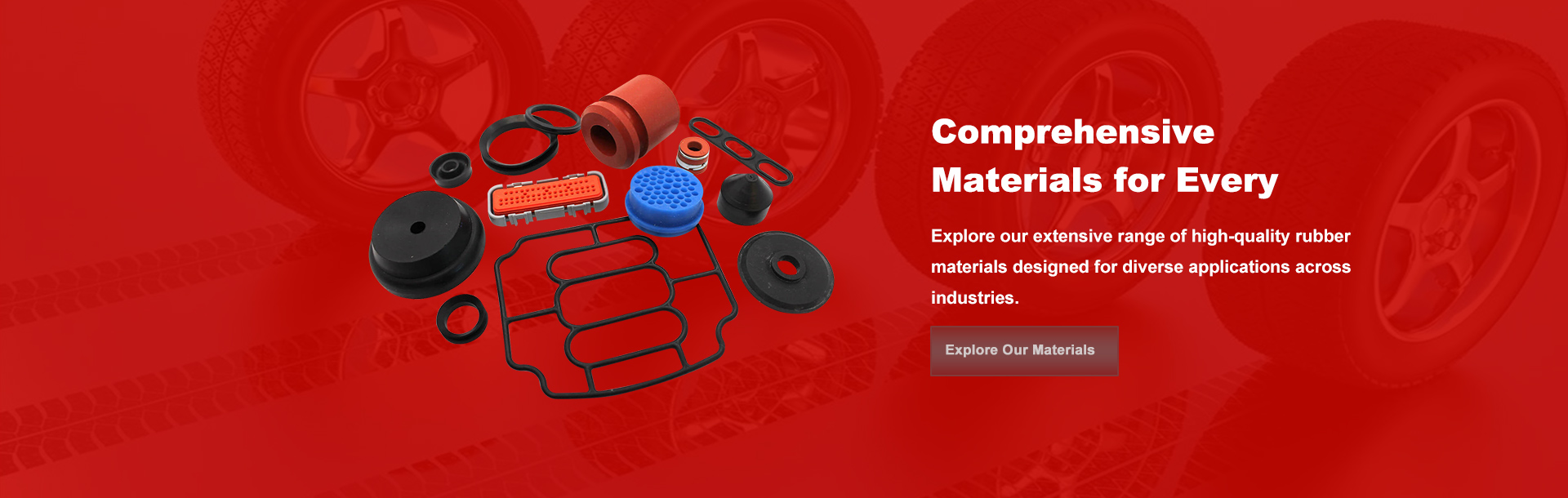

Arucoworld’s Aerospace Rubber Solutions

Arucoworld provides custom rubber components for the aerospace industry, including seals, gaskets, and vibration isolators. Our materials are designed to meet the rigorous performance standards of aerospace applications, ensuring reliability and safety in flight.

Challenges and Future Trends

The aerospace sector demands rubber materials that can withstand extreme thermal cycling, UV exposure, and mechanical stress without degrading. Future developments will focus on creating even more durable and heat-resistant rubbers to meet the needs of next-generation aircraft.

Conclusion

Rubber materials are integral to the aerospace industry's safety and performance. Arucoworld’s high-performance rubber solutions support aerospace applications with products that meet the highest standards of quality and durability.