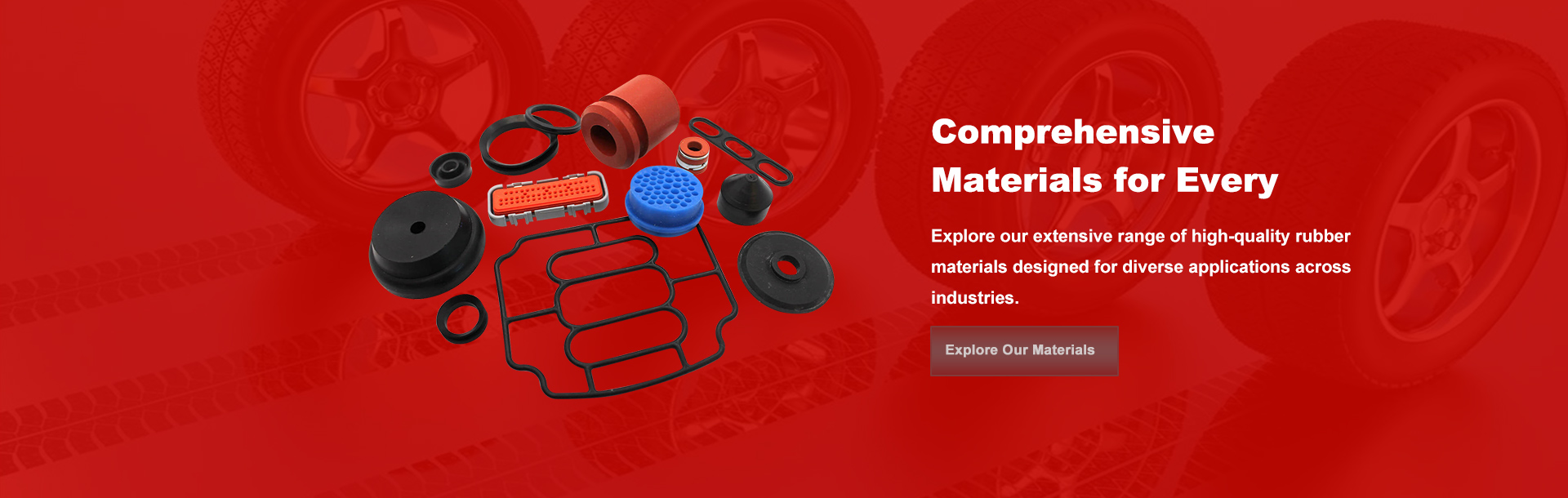

Introduction to Custom Rubber Gaskets

Rubber gaskets create essential seals in applications that require fluid, air, or contaminant isolation. These components are designed to fit specific equipment configurations, ensuring reliable sealing in a range of industries, from automotive to food processing.

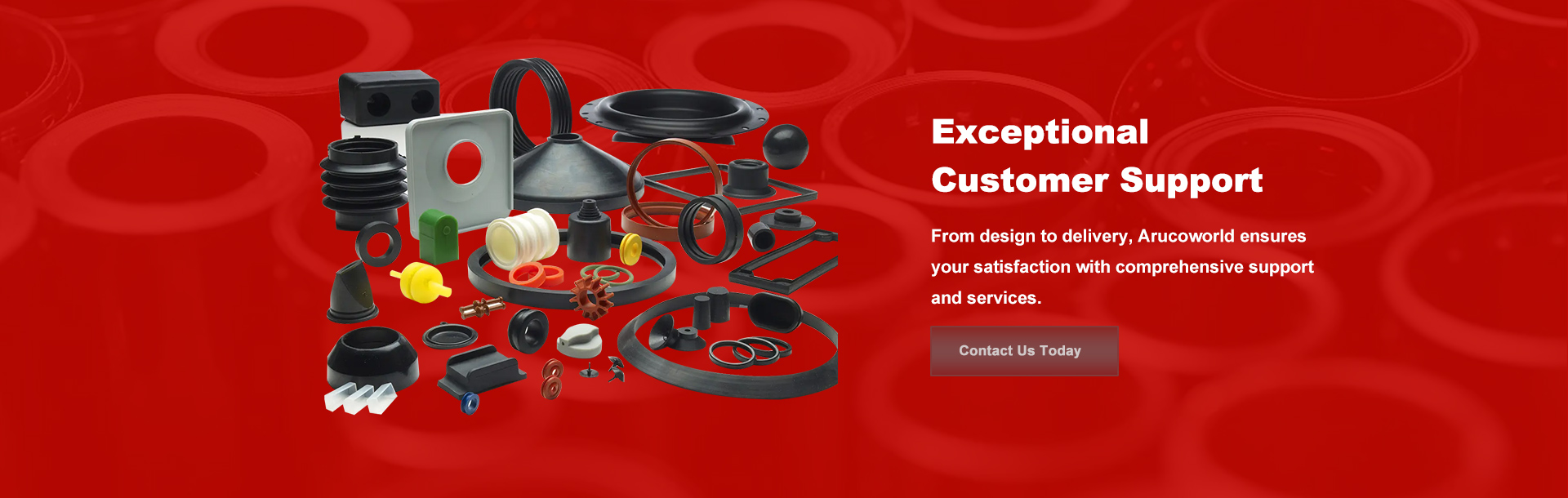

Why Custom Gaskets Matter

Custom rubber gaskets are tailored to meet unique specifications, which allows them to provide precise, durable seals in specialized applications. They are often used in environments where a standard gasket wouldn’t fit or wouldn’t withstand extreme conditions, such as high temperatures, pressure, or chemical exposure.

Arucoworld’s Custom Gasket Solutions

Arucoworld provides custom gasket solutions that offer superior fit and durability. Using advanced materials and design techniques, we produce gaskets that ensure effective sealing, minimizing leaks, and extending equipment life in critical applications.

Challenges in Gasket Production

Creating durable custom gaskets requires selecting materials that can withstand the specific conditions of each application, from chemical exposure to temperature extremes. Arucoworld’s commitment to quality includes rigorous testing to meet these demanding standards.

Future Trends in Gasket Solutions

New rubber compounds and manufacturing techniques, such as water-jet cutting and 3D printing, are enabling more precise and cost-effective gasket production. Advances in material science also promise gaskets with improved resilience to harsh chemicals and high pressures.

Conclusion

Custom rubber gaskets are vital for effective sealing in diverse industries. Arucoworld’s expertise in gasket manufacturing ensures reliable, high-quality seals that enhance equipment safety and efficiency.