Introduction to Rubber Solutions for Noise and Vibration

In industrial and consumer applications alike, managing noise and vibration is essential. Rubber solutions—such as mounts, pads, and dampeners—absorb sound and vibrations, improving comfort, safety, and equipment longevity. Industries like automotive, aerospace, and construction rely on these components to minimize operational noise and prevent vibration-related wear.

The Role of Rubber in Vibration and Noise Control

Rubber’s natural elasticity and damping properties make it highly effective in isolating vibrations. For instance, in the automotive industry, rubber mounts minimize engine vibration for a smoother ride, while in electronics, rubber gaskets reduce noise for quieter operation.

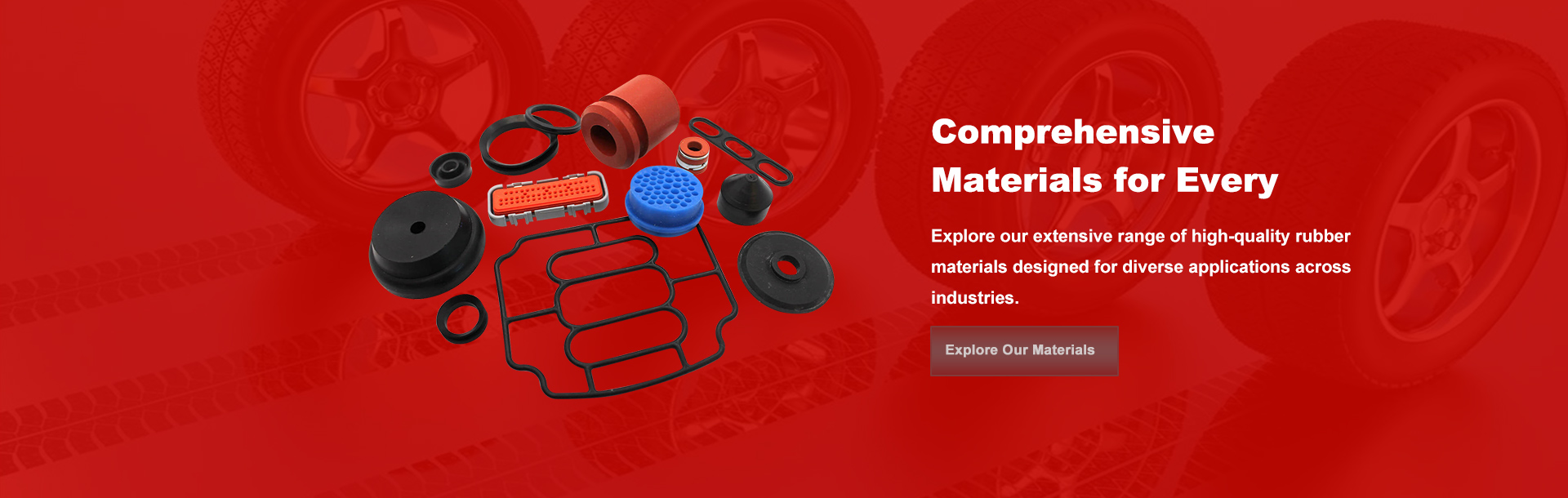

Arucoworld’s Rubber Solutions

Arucoworld specializes in designing and manufacturing rubber components tailored to control vibration and noise. Our products include custom vibration dampeners, engine mounts, and noise-reducing gaskets, each engineered for optimal performance under various load and frequency conditions.

Challenges in Noise and Vibration Control

Achieving effective vibration and noise control requires precision engineering and material selection. Arucoworld addresses these challenges by using high-quality rubber compounds and customized designs to ensure maximum noise and vibration isolation.

Future of Rubber in Noise and Vibration Control

New synthetic rubber materials, such as thermoplastic elastomers, offer improved damping properties. Additionally, advancements in material science and design will continue to refine the efficiency and durability of rubber-based noise and vibration solutions.

Conclusion

Rubber plays a key role in controlling noise and vibration across industries. Arucoworld’s high-quality, custom-engineered rubber solutions provide effective and durable noise and vibration control, enhancing comfort and extending equipment lifespan.