Introduction to Precision Sponge Rubber

Sponge rubber, available in both closed-cell and open-cell structures, offers versatile solutions for applications needing lightweight, flexible materials with excellent sealing and insulating properties. Its compressibility, combined with resistance to weather, chemicals, and water, makes sponge rubber ideal for automotive, electronics, and construction industries.

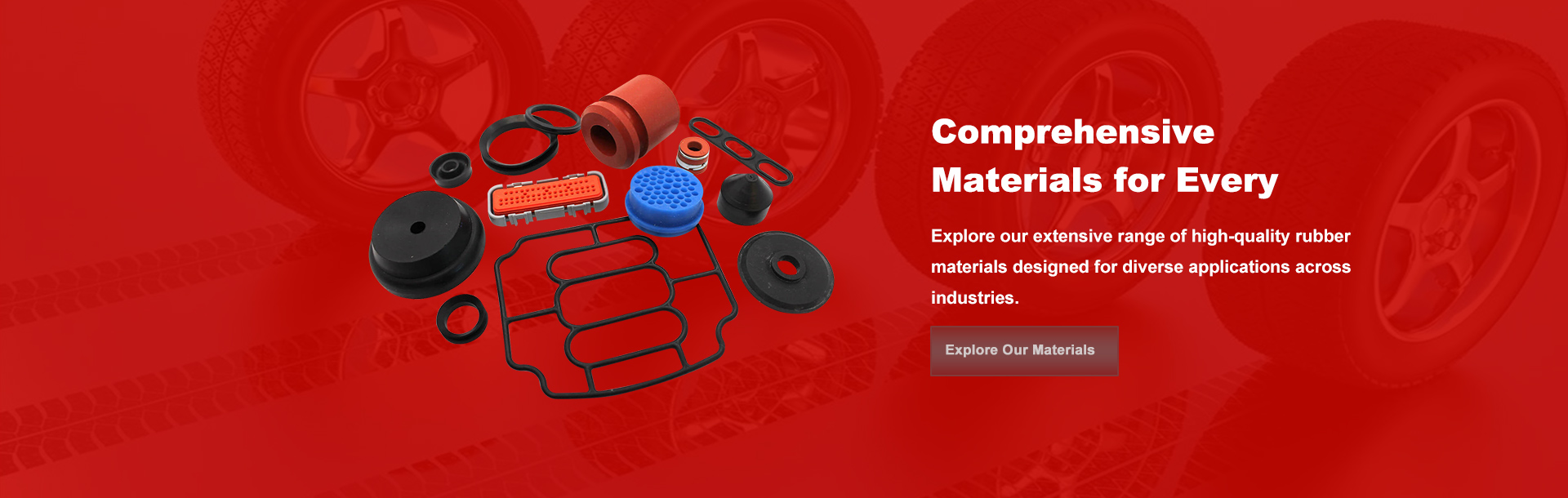

Why Sponge Rubber Is Essential

Precision-engineered sponge rubber components are vital for creating seals, gaskets, and pads in high-demand applications. The material’s unique structure allows it to provide cushioning, thermal insulation, and vibration dampening. In automotive applications, sponge rubber is used in weatherproof seals, while in electronics, it acts as an insulating barrier.

Arucoworld’s Expertise in Sponge Rubber Solutions

Arucoworld excels in producing precision sponge rubber components tailored to diverse applications. We work with both open and closed-cell sponge rubber, selecting materials based on required density, durability, and flexibility. Our solutions ensure effective sealing, insulating, and shock-absorbing properties, enhancing product performance and longevity.

Challenges in Sponge Rubber Production

Creating high-quality sponge rubber products requires careful control over material density and cell structure to ensure consistent performance. At Arucoworld, we apply rigorous quality standards to deliver products that meet specific application requirements, from automotive seals to industrial gaskets.

Future of Sponge Rubber Solutions

As demand for lightweight, energy-efficient materials rises, sponge rubber continues to evolve with innovations in material science and manufacturing. The integration of new polymers enhances resistance to extreme conditions, expanding sponge rubber’s applications across industries.

Conclusion

Sponge rubber offers critical solutions for industries seeking flexibility, insulation, and durability. Arucoworld’s precision-engineered sponge rubber products support diverse needs, ensuring reliability and performance in demanding environments.