Introduction to Custom Molded Rubber Products

Custom molded rubber products are integral to modern manufacturing, providing tailored solutions for specific applications across various industries. This process involves molding rubber into precise shapes, meeting the unique specifications required for automotive, medical, and industrial applications.

These custom rubber products are engineered to withstand harsh environments, offering durability, flexibility, and resistance to chemicals, heat, and wear. By catering to specific needs, custom rubber molding enhances efficiency, safety, and performance in critical applications.

Why Custom Molded Rubber Matters

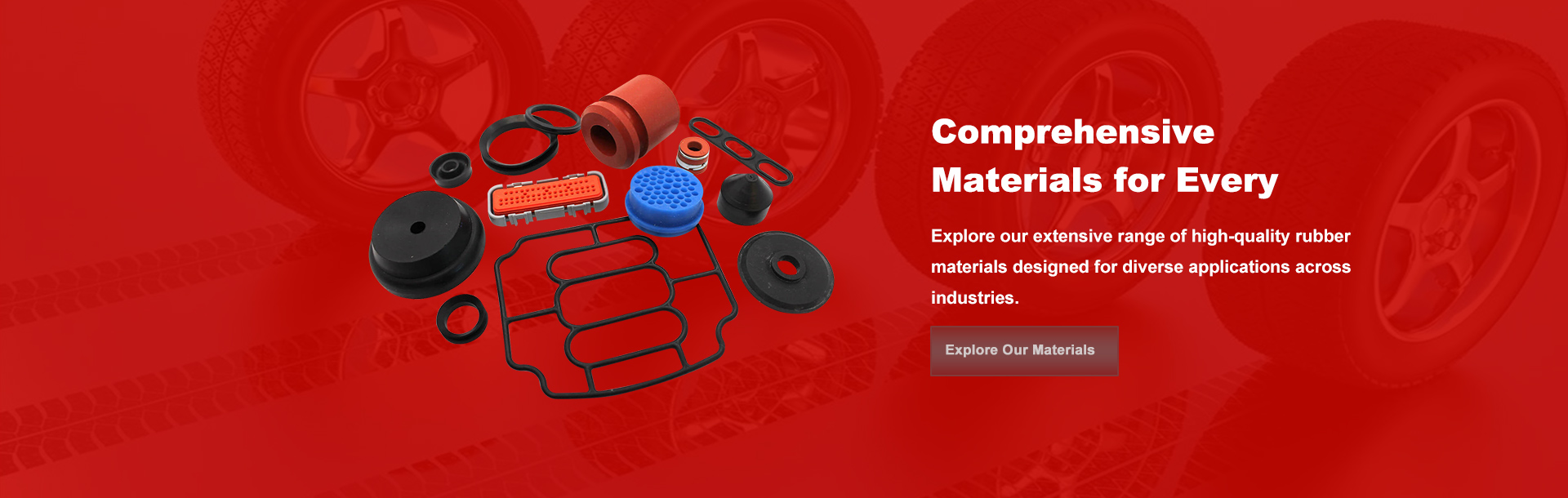

Custom molding allows manufacturers to address precise requirements, offering options like compression, injection, and transfer molding to produce complex shapes and features. This flexibility enables manufacturers to create parts that align perfectly with application demands, reducing material waste and optimizing performance.

In industries like automotive, molded rubber products serve as seals, grommets, and shock absorbers, protecting components from heat and vibration. Medical equipment also relies on custom rubber parts for safety and biocompatibility, while industrial applications use them for gaskets, bushings, and isolators that endure rigorous conditions.

Arucoworld’s Approach to Custom Molding

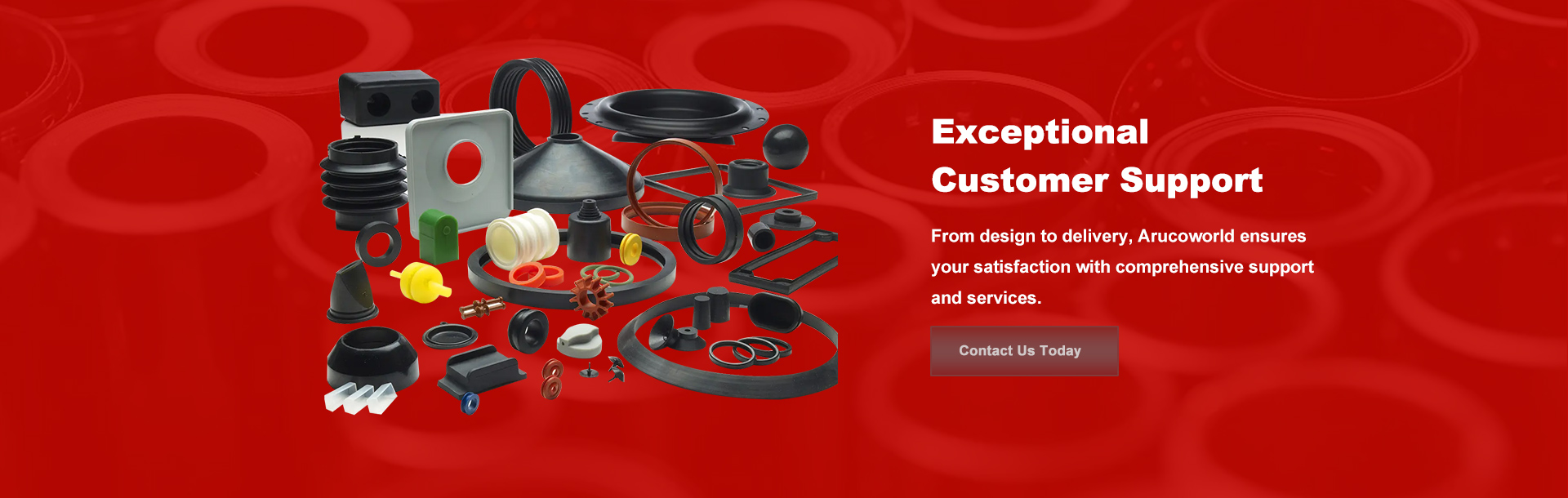

Arucoworld specializes in creating high-quality, custom-molded rubber solutions for varied industries. Our process includes selecting the appropriate molding technique and material to meet each client’s exacting specifications. Using advanced molding technologies, we deliver parts that maintain their integrity under challenging conditions, ensuring optimal performance and durability.

Challenges in Custom Molded Rubber Production

Producing custom-molded rubber components comes with challenges, including material selection, mold precision, and quality control. For Arucoworld, close attention to material properties and rigorous testing are essential to ensure that each product meets strict performance standards.

Future Trends in Custom Rubber Molding

As industries demand greater customization, innovations in molding techniques and materials continue to advance. Automation in custom rubber molding promises improved quality, while eco-friendly materials are on the rise to meet sustainability goals.

Conclusion

Custom-molded rubber products are crucial in modern manufacturing, allowing companies to meet application-specific requirements. Arucoworld’s commitment to precision and quality ensures that our custom rubber solutions support safety, durability, and efficiency across industries.